In the realm of manufacturing environments, Radiant Technology stands out as a leader in cutting-edge digital signage ecosystems tailored to enhance operational efficiency, safety and culture. Harnessing the potential of data visualization and workflow automation has emerged as a game-changer in creating smart manufacturing environments. By combining visual insights with automated processes, manufacturers can unlock efficiency, productivity, and informed decision-making. For the employees, the benefits are even greater as they can drive culture through safety, buy-in, engagement and innovation. Let’s dive deeper to learn how Radiant Technology Group partners with clients to modernize the manufacturing environment.

Our expertise lies in the transformation of conventional manufacturing signage, consolidating it into a unified digital canvas that unlocks endless creative possibilities and generates a tangible impact for our clients. Most manufacturers that have digitized different areas of their environments are now plagued with having to manage and support multiple platforms, vendors and training workflows and have little control of integrating these platforms for specific needs and into other workflows. With a unified platform that can address all areas and meticulous integration of data from all silos of the enterprise, our team creates custom dashboards with visual calls to action, propelling your operations toward a transformational, LEAN state.

Are you interested in learning more about digital transformations?

Download our Guidebook

At Radiant Technology, we are committed to revolutionizing the manufacturing experience with our unrivaled proficiency in driving impactful changes through digital signage technology.

In today’s dynamic manufacturing landscape, data, and data visualization has become a crucial asset for businesses aiming to gain a competitive edge.

How Radiant Technology Group Builds Smart Manufacturing Signage Environments

By consolidating systems and signage platforms used across the enterprise, Radiant helps the manufacturer identify areas for cost savings and increased efficiencies throughout the production plant.

Key data points are pulled into a consolidated platform and are then optimally visualized on dashboards. This organizes and displays relevant information to key stakeholders, which accelerates the decision-making processes from months to weeks.

Our scalable digital signage solution distributes targeted messaging and data across multiple locations, so the right message reaches the right audience at the right time.

The role of data visualization in smart manufacturing

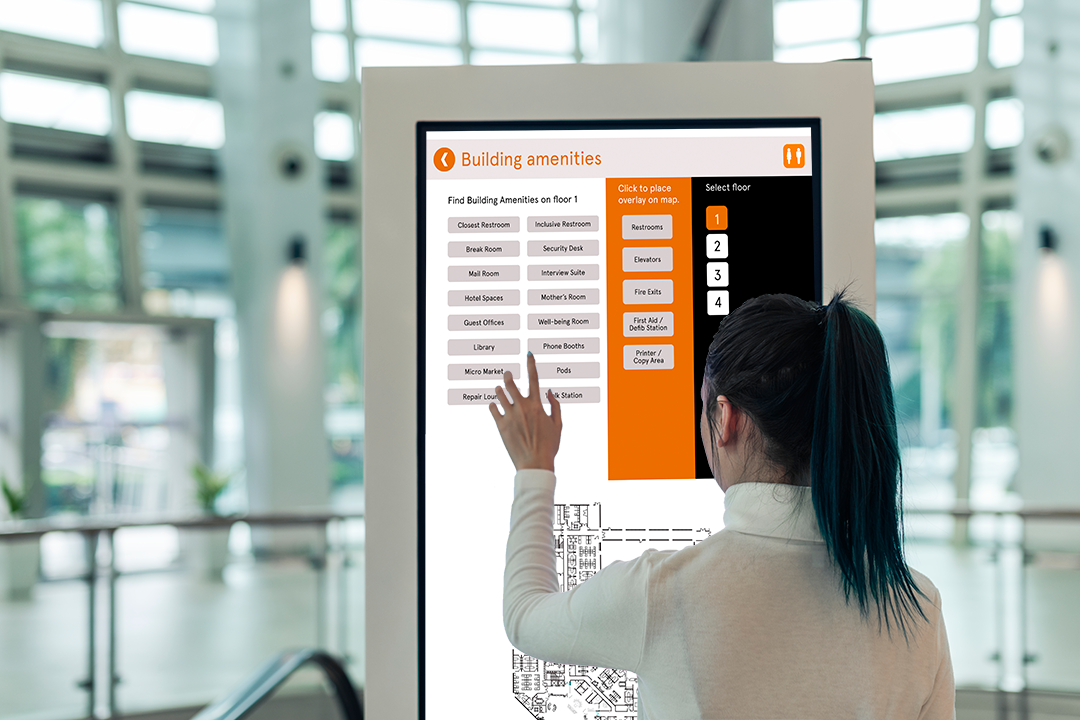

Data visualization is a powerful tool that simplifies complex datasets into intuitive visual representations. This enables stakeholders on the manufacturing floor, and decision-makers, both in person and remote, to gain valuable insights and make decisions that are backed by real-time data and analytics.

“Data visualization enables team members to identify issues and opportunities for continuous improvements immediately, process them, see the impacts of small incremental changes more clearly and impact sustainability and quality more quickly. Our manufacturing clients, including those in the automotive industry have reported Kaizen events being cut from six-eight months to three to six weeks after implementing our data visualization solutions.”

Effective data visualization enables stakeholders to gain valuable insights and make data-driven decisions, in real-time when every second counts, leading to greater efficiency. Manufacturers can leverage visualization techniques including charts, graphs, dashboards, and heatmaps to monitor operations, identify bottlenecks, and track performance in real-time. Effective data visualization improves operational efficiency, enhances quality control, and facilitates proactive decision-making.

With integration of all types of data sources, not just from data systems, SDKs and API, but directly from IoT devices, process and cell management can significantly reduce errors which can be costly due to inexperience from newer line workers or even line fatigue from those with more experience. Each step of the process can be triggered with clear timely instructions and review during a process and even automatically flag events which may impact safety, quality or delivery and automatically notify supervisors for awareness and tracking.

The Outcome: Data visualization allows manufacturers to see visual calls to action, preventing breakdowns and speeding up decision-making time, resulting in more efficient workflows.

The power of automated triggers in smart manufacturing

Automation of visual triggers assist in streamlining and optimizing manufacturing workflows. By setting visual triggers we help our clients prevent breakdowns and bottlenecks before they happen. Automated triggers in manufacturing environments help to eliminate human error, reduce cycle times, and improve efficiency.

How Radiant does it: Our team of experts works as an extension of your team, learning what causes bottlenecks, production issues and breakdowns. We then create visual calls to action unique to your environment to help your teams work more efficiently.

The outcome: These visual calls to action speed production times and result in more efficient and safer manufacturing environments.

Convergence of data visualization and automation in manufacturing

The true power of data-driven manufacturing lies in the convergence of data visualization and automation. These technologies create smart manufacturing environments that deliver visibility, control, and agility. Data visualization provides a user-friendly interface to interpret manufacturing data, while automation ensures efficient execution based on these insights. The convergence enables a holistic view of operations, pattern identification, anomaly detection, and performance optimization. It also enables proactive decision-making and continuous process improvement.

The outcome: By consolidating data and combining it with automation you can digitally transform your environment into a more efficient, safer manufacturing facility. This results in greater efficiency and higher productivity that leads to bigger profits.

Best Practices for implementing visualization and automation in manufacturing

Implementing data visualization and automation requires careful planning and execution. When partnering with Radiant Technology Group for Vision Building and Blueprint services, we create a plan that will optimize your data and set it into motion. Key considerations for data visualization in manufacturing include data quality, integration challenges, and change management. Regular evaluation and refinement are crucial for continuous improvement.

Partner with Radiant Technology to transform your manufacturing environment

Data visualization and automation are transforming the manufacturing industry, turning traditional manufacturing environments into data-driven powerhouses. By harnessing the insights provided by data visualization and automating critical processes, manufacturers unlock efficiency, productivity, and informed decision-making. The convergence of these technologies enables proactive decision-making, real-time monitoring, and continuous improvement.

Manufacturers must embrace these technologies, adopt best practices, and navigate challenges to thrive in the data-driven future of manufacturing. The journey towards becoming a data-driven factory begins by leveraging the power of visualization and automation.